This is the optimal solution for:

- Paint Finishing Systems

- Robotic Welding

- Robotic Assembly

- Machine-to-Machine Transfers

- General Assembly

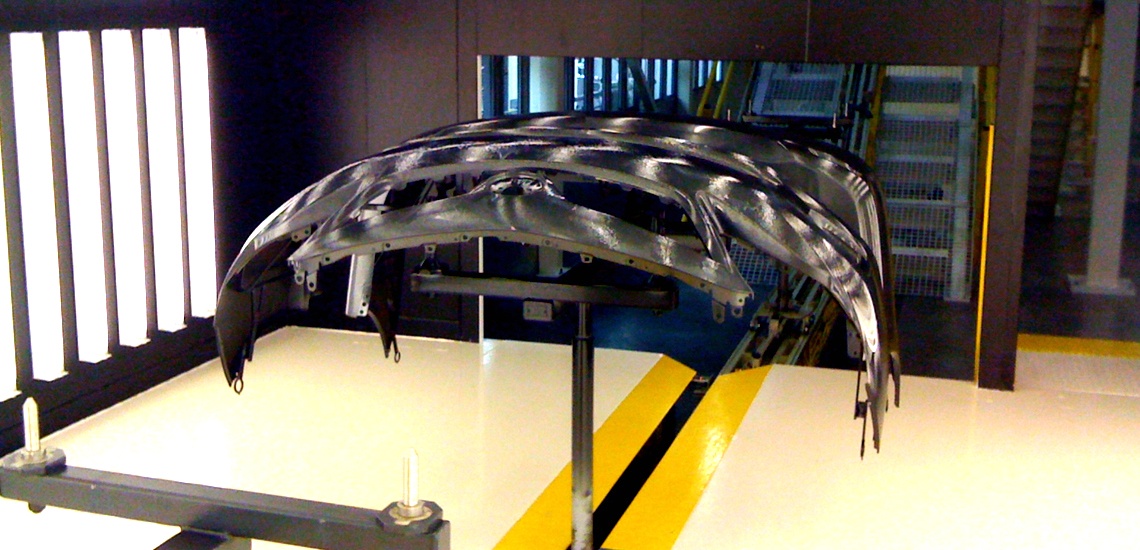

The OveR-Way™ Inverted system features:

- Modular Components: It utilizes standard enclosed track components pre-welded at the factory, making the system simple to install, maintain and change.

- Extreme Stability: It’s designed with an additional guide track to provide unparalleled stability where position accuracy is critical.

- A Self-Supporting Structure: This system requires no hanging or header steel. All structural support is provided within the design itself.

- High Capacity: Ranging from 10 to 1,000 pounds.

Engineered For Evolution

The Richards-Wilcox OveR-Way™ Inverted Power & Free Conveyor is engineered to evolve your factory.

Here’s how:

- The system optimizes production rates by integrating processes typically serviced by multiple types of conveying equipment.

- OveR-Way™ Inverted is designed to keep your products clean. All components are positioned below the product to eliminate contamination.

- Our engineers can adjust the work surface for optimal ergonomics.

- OveR-Way™ Inverted is perfect for systems with robotics. It provides 360 degrees of accessibility to the top and sides of the product, making it truly robot-friendly.

- The system consumes substantially less energy than conventional assembly line conveyors.