Richards-Wilcox control systems feature:

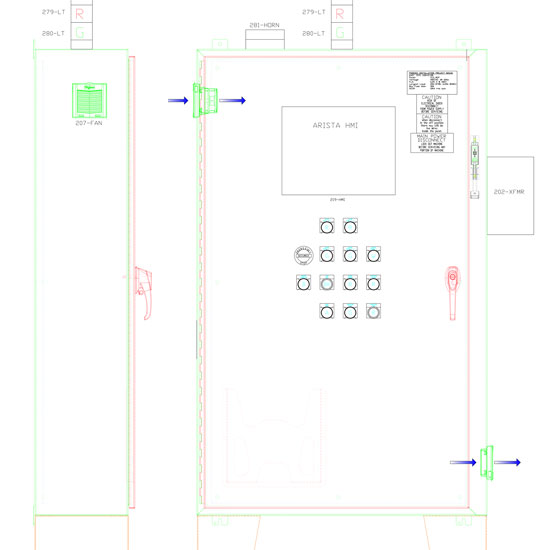

- Operator Interface Displays for on-line process status or input to system functions

- Graphical User Interface (GUI) that allows the operator to see real-time production information. This increases efficiency and enables the operator to exchange information with other departments and personnel

- Complete operation and maintenance training along with support documentation

- Carrier ID, RFID, or Bar Code Tags and Readers designed for harsh manufacturing environments

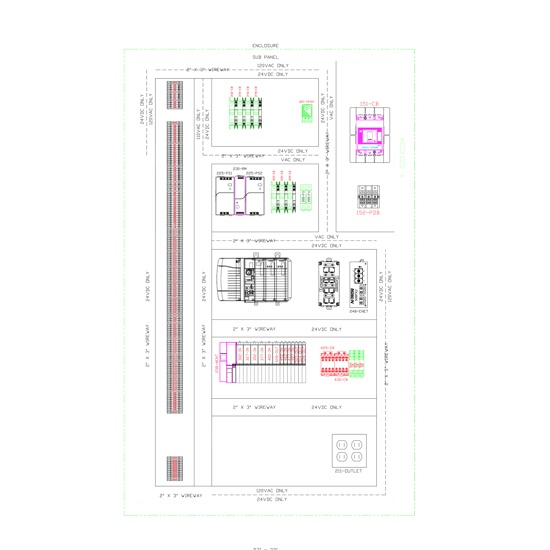

- Highly recognized industrial components, latest hardware platforms, open system architecture and easy-to-use software configurations

- Easy installation, operation and maintenance

- Emergency shut-down capabilities from any location

- All requirements of NEC, OSHA, UL, and JIC specifications

Engineered For Evolution

The Richards-Wilcox Control System Benefits Put You On The Path To Evolution.

Here’s how:

- Enables system integration with host computer or other software systems

- Allows for variable production rates and quick production changes

- Expandable and flexible controls improve workflow and meet new requirements

- System Control Software simplifies maintenance and debugging of system

- Richards-Wilcox provides complete operator and maintenance training along with complete controls documentation

- System automatically shuts down in the event of malfunction

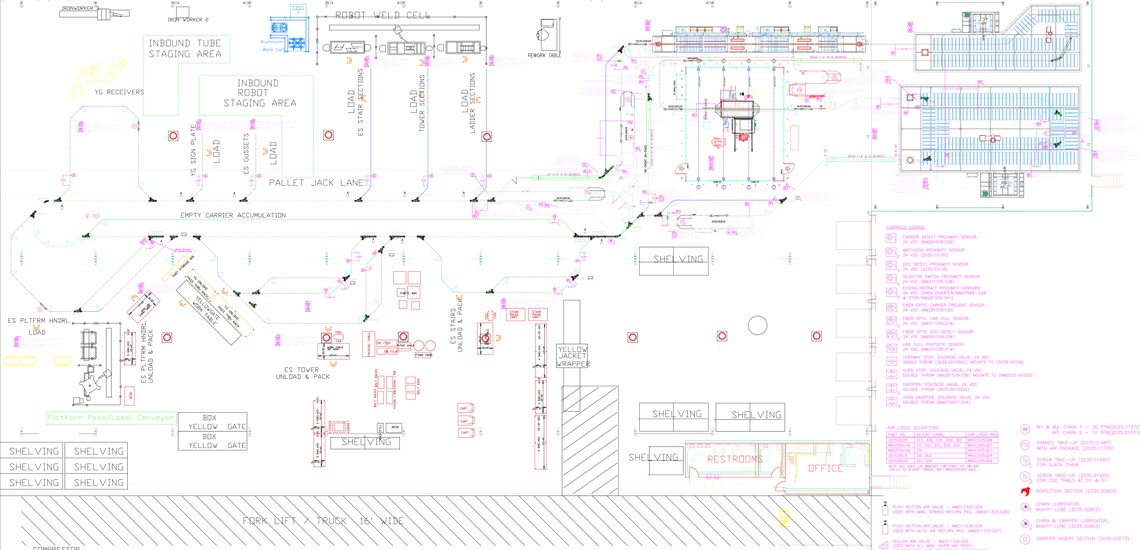

- Helps you collect, view, store, control, analyze and manage conveyor information from your plant floor with ease

- Creates simulations to provide an evaluation of new ideas for optimizing the conveyor system before implementation

- Programmable Logic Controls (PLC’s) enable direct system control

Richards-Wilcox provides comprehensive, ongoing support for the life of your system, including:

- Education and Training

- Simulation

- Modernization

- Customer Support

- Customer Service

- Parts replacement