Industry 4.0 – The New Breed of Evolution

Today, we live in the world of Industry 4.0. Manufacturing and distribution operations are getting faster, smarter, leaner, more advanced. It’s a jungle out there. To survive, you have to be efficient, effective and ready to adapt at a moment’s notice.

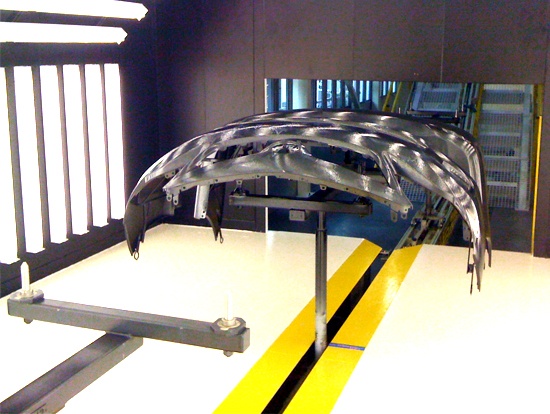

It all starts with your conveyor.